-

Hydraulic Hose Crimping Machine

-

Hose Crimping Machine

-

Manual Hose Crimping Machine

-

Rubber Hose Crimping Machine

-

Dx68 Hose Crimping Machine

-

AC Hose Crimping Machine

-

Used Hydraulic Hose Crimping Machine

-

Portable Hydraulic Hose Crimper

-

Brake Hose Crimping Machine

-

Hose Pressing Machine

-

12v Hydraulic Hose Crimper

-

High Pressure Hose Crimper

-

Hose Cutting Machine

-

Hose Skiving Machine

-

Hydraulic Rubber Hose

-

Hydraulic Hose Fittings

-

Hydraulic Hose Ferrule

-

DenniesThe machines are awesome! I highly recommend this product from a reliable supplier. Thank you for the quick and immediate respond to my inquiries. Looking forward to future transactions with you.

DenniesThe machines are awesome! I highly recommend this product from a reliable supplier. Thank you for the quick and immediate respond to my inquiries. Looking forward to future transactions with you. -

JohnWe got the goods very quickly, and we have tested, good quality of the machines.

JohnWe got the goods very quickly, and we have tested, good quality of the machines.

High Pressure Hose Crimper Hydraulic Hose Press Hydraulic Pipe Repairing Machine

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Crimping Range | 14 - 87mm | Hose Size | 1/4 - 2.5inch |

|---|---|---|---|

| Die Sets | 13 | Color | Blue |

| Max. Opening | 31mm | Crimping Force | 650T |

| Product Name | NC130-I High Pressure Hose Crimper | Application | Workshop |

| System Pressure | 31.5Mpa | Power | 3.75KW |

| Size | 650*550*1360mm | Weight | 310Kg |

| Highlight | 2.5inch High Pressure Hose Crimper,NC130-I High Pressure Hose Crimper,NC130-I High Pressure Hose Crimping Tool |

||

HIGH PRESSURE HOSE CRIMPER MS-NC130-I

DESCRIPTION

MS-NC130-I high pressure hose crimping machine is suitable for hydraulic high pressure rubber hose assembly fabrocating, brake line pipes pressing, air conditioner hose crimping. It is widely used globally in the industries like car automotive system, marine, construction machinery, engineering machinery, etc.

ADVANTAGES

1. Pedal switch control the closing of the die sets, free hands for holding hose

2. Famous PLC control system with stable performance

3. Unique hydraulic cylinder design, low maintenance cost

4. Soft screen panel, easy and convenient

5. Quick mold change to improve the efficiency

TECHNICAL DATA

|

Model |

MS-NC130-I Hose Crimper |

|

Crimping Range |

14 - 87 (mm) |

|

Crimping Force |

650 (T) |

|

Hose Size |

1/4 - 2.5 (inch) |

|

Max. Opening |

31 (mm) |

|

Die Sets |

13 |

|

Die Set Type |

P32 |

|

System Pressure |

31.5 (Mpa) |

|

Accuracy |

0.01 (mm) |

|

Control |

UC Digital Control |

|

Standard Voltage |

220 (V) / 380 (V) |

|

Motor Power |

3.75 (KW) |

|

Length |

650 (mm) |

|

Width |

550 (mm) |

|

Height |

1360 (mm) |

|

Weight |

310 (KG) |

![]()

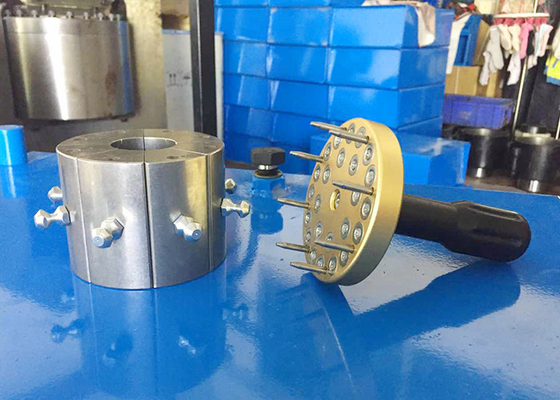

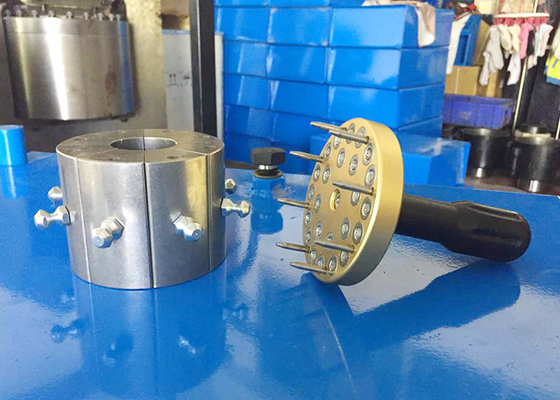

P32 HOSE CRIMPER DIE SETS

|

Die No. # |

Crimping (mm) |

Length (mm) |

|

6* |

6.0 - 8.0 |

55 |

|

8* |

8.0 - 10.0 |

55 |

|

10* |

10.0 - 12.0 |

55 |

|

12* |

12.0 - 14.0 |

55 |

|

14 |

14.0 - 16.0 |

55 |

|

16 |

16.0 - 19.0 |

55 |

|

19 |

19.0 - 22.0 |

55 |

|

22 |

22.0 - 26.0 |

70 |

|

26 |

26.0 - 30.0 |

70 |

|

30 |

30.0 - 34.0 |

70 |

|

34 |

34.0 - 39.0 |

75 |

|

39 |

39.0 - 45.0 |

75 |

|

45 |

45.0 - 51.0 |

90 |

|

51 |

51.0 - 57.0 |

90 |

|

57 |

57.0 - 63.0 |

100 |

|

63 |

63.0 - 69.0 |

110 |

|

69 |

69.0 - 74.0 |

110 |

| 74* | 74.0 - 78.0 | 110 |

| 78* | 78.0 - 87.0 | 110 |

NOTICE

• " * " for non standard mold

• Max. opening is the working stroke of cylinder

• Customized die sets are available

• Special voltage 110V, 208V, 240V, 415V, 440V are availbale

• MS control as optional

DEATILED PICTURES

► Advanced design for cylinder and master die, enable high force and synchronous movement

![]()

► 13 die sets place in the special rack which can also let the main machine part mounted

![]()

► PLC control system with high intelligent level, showing crimping diameter actural time movement

![]()

SAMPLES DETAILS

![]()